● The mixing cylinder of this machine has multi-directional movement, no centrifugal force of the material, incomparable heavy segregation and delamination, accumulation phenomenon, each component can have a disparity in weight ratio, high mixing rate, is currently the ideal product in various mixers. ● Large cylinder loading rate, up to 90% (ordinary mixer is only 50%), high efficiency, short mixing time. ● The whole part of the cylinder is an arc transition, which has been precision polished. ● Used in pharmaceutical, chemical, food, light industry, electronics, machinery, mining and metallurgy and other industries. ● High uniformity mixing of powdered and granular materials in the national defense industry and various scientific research units.Mixing barrel is suspended on ends of driving and driven axles through two Y type universal joints that are crossing and vertical to each other in the space. When driving axle is driven to rotate, universal joint makes the barrel perform composite motion including horizontal moving, rotating and turning etc, in the space, by which, materials also performs 3-dimensional motion inside the barrel. Several kinds of materials inside the barrel flow, diffuse, penetrate each other and finally form uniform status. Structure: The machine is composed of the base, transmission system, electrical control system, multi-directional motion mechanism, mixing barrel and other components, and the mixing barrel in direct contact with the material is made of stainless steel material, and the inner and outer walls of the barrel are polished. Fully compliant with GMP requirements.

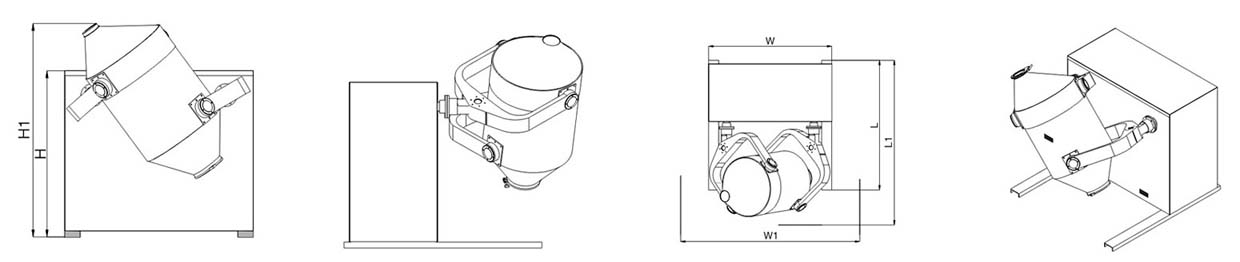

● The mixing cylinder of this machine has multi-directional movement, no centrifugal force of the material, incomparable heavy segregation and delamination, accumulation phenomenon, each component can have a disparity in weight ratio, high mixing rate, is currently the ideal product in various mixers. ● Large cylinder loading rate, up to 90% (ordinary mixer is only 50%), high efficiency, short mixing time. ● The whole part of the cylinder is an arc transition, which has been precision polished. ● Used in pharmaceutical, chemical, food, light industry, electronics, machinery, mining and metallurgy and other industries. ● High uniformity mixing of powdered and granular materials in the national defense industry and various scientific research units.Mixing barrel is suspended on ends of driving and driven axles through two Y type universal joints that are crossing and vertical to each other in the space. When driving axle is driven to rotate, universal joint makes the barrel perform composite motion including horizontal moving, rotating and turning etc, in the space, by which, materials also performs 3-dimensional motion inside the barrel. Several kinds of materials inside the barrel flow, diffuse, penetrate each other and finally form uniform status. Structure: The machine is composed of the base, transmission system, electrical control system, multi-directional motion mechanism, mixing barrel and other components, and the mixing barrel in direct contact with the material is made of stainless steel material, and the inner and outer walls of the barrel are polished. Fully compliant with GMP requirements.| Model | Barrel volume | Mixing capacity | Spindle speed(r/min) | Power(kw) | Overall dimension (length, width and height mm) | Weight(kg) |

| CF-SWH-50 | 50L | 40L | 0-20 | 1.1 | 1150*1400*1320 | 300 |

| CF-SWH-100 | 100L | 80L | 0-20 | 1.5 | 1250*1400*1500 | 800 |

| CF-SWH-200 | 200L | 160L | 0-15 | 2.2 | 1350*1400*1500 | 1200 |

| CF-SWH-400 | 400L | 320L | 0-15 | 4 | 1450-2000*1500 | 1200 |

| CF-SWH-600 | 600L | 480L | 0-13 | 5.5 | 1650*2200*1500 | 1500 |

| CF-SWH-800 | 800L | 640L | 0-10 | 7.5 | 2100*2650*2000 | 1700 |

| CF-SWH-1000 | 1000L | 800L | 0-10 | 7.5 | 2150*2800*2100 | 1800 |

| CF-SWH-1200 | 1200L | 960L | 0-9 | 11 | 2000*3000*2260 | 2000 |

| CF-SWH-1500 | 1500L | 1200L | 0-9 | 15 | 2300*3200*2500 | 2400 |

| CF-SWH-2000 | 2000L | 1600L | 0-8 | 18.5 | 2500*3600*2800 | 3000 |